Mining operations in Australia require equipment and materials that can withstand some of the harshest conditions on the planet. One of the essential components in these operations is the mining trailing cable, a specialized cable designed to power and control heavy machinery.

These cables need to be tough, reliable, and adaptable to the ever-changing conditions of a mining environment. But what makes these cables truly unique and suitable for mining operations? The answer lies in a particular feature: the Central Extensible Pilot.

In this article, we'll explore what the Central Extensible Pilot is, why it's vital in mining trailing cables, and the role it plays in meeting the rigorous standards set by the Australian AS/NZS 2802 standard.

We’ll also discuss how this component enhances the safety, functionality, and longevity of trailing cables, making it indispensable for mining operations across the country.

Before diving into the details of the Central Extensible Pilot, it's crucial to understand the overall structure of a mining trailing cable. These cables are designed to deliver power to mobile mining equipment such as shovels, drills, and draglines. The rugged environment of mining operations demands that these cables are not only strong but also flexible and resistant to wear and tear.

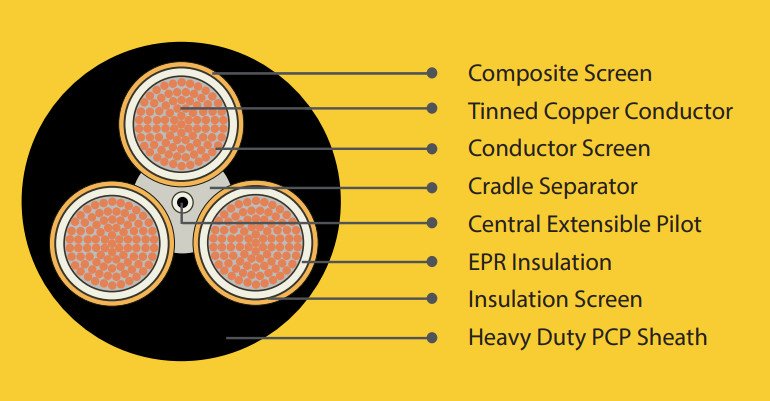

A typical mining trailing cable consists of several layers, including:

Conductors: These carry electrical power to the machinery.

Insulation: This protects the conductors from electrical leakage and physical damage.

Protective Layers: These include layers of armoring and sheathing that shield the cable from mechanical stress, moisture, chemicals, and other environmental factors.

Central Extensible Pilot: This is the feature that sets mining trailing cables apart, providing both safety and communication functions.

The Central Extensible Pilot is a core component found within the structure of mining trailing cables.

It is typically a smaller conductor located at the center of the cable, surrounded by the main power conductors and insulation. But what makes it so essential?

The primary purpose of the Central Extensible Pilot is to serve as a monitoring and safety device. It continuously checks the integrity of the cable, ensuring that any faults or damages are detected early.

This is particularly important in mining operations, where a damaged cable can lead to catastrophic failures or accidents.

Safety is paramount in any mining operation, and the Central Extensible Pilot plays a crucial role in maintaining it. This conductor is responsible for monitoring the cable's condition throughout its use.

If a fault or potential breakdown is detected, the Central Extensible Pilot can trigger an immediate shutdown of the power supply. This prevents the machinery from operating with a compromised cable, reducing the risk of electrical fires, equipment damage, or even injury to personnel.

The Australian AS/NZS 2802 standard emphasizes the importance of safety in mining trailing cables, and the inclusion of a Central Extensible Pilot is a critical requirement.

By incorporating this feature, cable manufacturers ensure that their products meet the stringent safety standards necessary for use in Australian mines.

In addition to enhancing safety, the Central Extensible Pilot also facilitates communication between the machinery and the control systems. It can transmit signals that help operators monitor the performance of the equipment and the condition of the cable.

This real-time communication is vital for the efficient operation of mining machinery, allowing for immediate adjustments and reducing downtime.

For example, if the Central Extensible Pilot detects a potential issue, it can send a signal to the control system to alert the operators.

This early warning system enables the maintenance team to address the problem before it escalates, keeping the machinery running smoothly and minimizing disruptions to the mining operation.

The mining environment is harsh, with cables exposed to extreme conditions such as high tension, abrasion, and exposure to chemicals and moisture.

The Central Extensible Pilot contributes to the longevity and durability of the mining trailing cable by ensuring that any issues are detected early.

By preventing the cable from operating under unsafe conditions, the Central Extensible Pilot reduces the wear and tear on the cable, extending its lifespan.

The Australian AS/NZS 2802 standard also highlights the importance of durability in mining cables, and the Central Extensible Pilot is a key feature that helps meet these requirements.

By maintaining the integrity of the cable over time, it ensures that the cable can withstand the rigors of the mining environment and continue to perform reliably.

The Australian AS/NZS 2802 standard sets out the requirements for electrical cables used in mining operations, focusing on safety, durability, and performance. The inclusion of the Central Extensible Pilot in mining trailing cables is not just a recommendation but a necessity for compliance with this standard.

The AS/NZS 2802 standard mandates that mining cables must be equipped with safety features that can detect faults and prevent accidents. The Central Extensible Pilot fulfills this requirement by providing a continuous monitoring system that can shut down the power supply if any issues are detected.

This proactive approach to safety aligns with the standard's goals of minimizing risks and ensuring the safe operation of mining equipment.

Moreover, the Central Extensible Pilot also helps manufacturers achieve the durability standards outlined in AS/NZS 2802.

By monitoring the cable's condition and preventing it from being used in unsafe conditions, this component contributes to the overall longevity of the cable. This ensures that the cable can meet the demands of the mining environment while maintaining its performance over time.

In the challenging and often dangerous world of mining, the Central Extensible Pilot plays a pivotal role in ensuring the safety, communication, and durability of mining trailing cables.

Its ability to monitor the cable's condition, detect faults early, and comply with the stringent AS/NZS 2802 standard makes it an indispensable feature in any mining trailing cable used in Australia.

For mining operators and equipment manufacturers, understanding the importance of the Central Extensible Pilot is crucial for selecting the right cable for their operations. By choosing cables equipped with this feature, they can enhance the safety and efficiency of their mining operations, reduce downtime, and ensure compliance with Australian standards.

If you're looking for reliable, durable, and compliant mining trailing cables, make sure they include the Central Extensible Pilot as a key component. It’s not just about meeting standards; it’s about ensuring the safety and success of your mining operation.

Q1: Why is the Central Extensible Pilot crucial in mining trailing cables?

A1: The Central Extensible Pilot enhances safety by monitoring the cable's condition and detecting faults early. It also facilitates communication between the machinery and control systems, ensuring smooth operation and reducing downtime.

Q2: How does the Central Extensible Pilot contribute to the cable's durability?

A2: By preventing the cable from operating under unsafe conditions, the Central Extensible Pilot reduces wear and tear, extending the cable's lifespan and ensuring it can withstand the harsh conditions of the mining environment.

Q3: Is the Central Extensible Pilot a requirement under the Australian AS/NZS 2802 standard?

A3: Yes, the AS/NZS 2802 standard mandates the inclusion of safety features like the Central Extensible Pilot in mining trailing cables to ensure compliance with safety and durability requirements.

Q4: Can the Central Extensible Pilot improve communication in mining operations?

A4: Absolutely. The Central Extensible Pilot transmits signals that help operators monitor the performance of the equipment and the cable, enabling real-time adjustments and minimizing disruptions to the mining operation.