What is Nylon Cable?

In today's fast-paced industrial landscape, the materials used in cable manufacturing have become as critical as the technology they support.

Among the most popular choices is nylon cable, a versatile and durable option that plays a key role in various applications.

But what exactly is nylon cable? How does it compare to other materials, like PUR? And why is it so widely used?

This guide will break down everything you need to know about nylon cables, from their unique characteristics to their common uses and how they stand out from other cable types. We’ll also explore their differences with PUR cables, another popular material choice.

The Basics of Nylon Cable

Nylon is a type of thermoplastic that belongs to the polyamide family. First developed in the 1930s, nylon was originally created as a synthetic replacement for silk and was primarily used in textiles.

Over the years, nylon has found a home in a wide array of industries due to its unique properties, particularly in the world of cable insulation and sheathing.

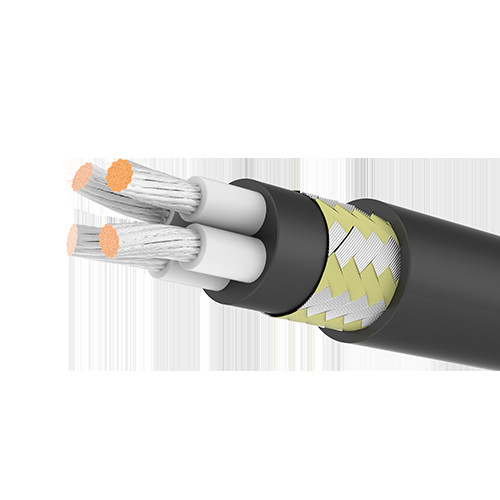

Nylon cables are recognized for their abrasion resistance, strength, and ability to be processed into various forms such as fibers, films, and extrudates.

This makes them ideal for industrial applications that require durability and flexibility. Because nylon can be blended with various additives, manufacturers can customize its properties for different uses.

Key Characteristics of Nylon Cable

Nylon offers several key characteristics that make it a popular choice for cable insulation and sheathing. Some of its standout properties include:

High abrasion resistance: Nylon's toughness ensures that it can withstand rough conditions without significant wear and tear. This makes nylon ideal for environments where cables may experience heavy friction or contact with rough surfaces.

Good mechanical strength: Nylon cables are strong, ensuring they can endure high levels of stress without breaking.

Smooth surface: The silk-like texture of nylon makes it easy to handle and reduces friction in some applications, such as threading through conduit.

Resistance to oils and solvents: Nylon is resistant to oils, alkalis, and a variety of organic solvents, making it suitable for environments where exposure to these substances is common.

However, nylon also has some limitations. For example, while it can resist oils and solvents, its resistance to acids is only moderate.

Additionally, nylon is flammable and doesn’t perform well under very high temperatures. It also has a slight tendency to absorb moisture, which can reduce its overall performance in certain applications, such as power cables.

Nylon Cable Processing

When it comes to production, nylon compounds are typically made by specialized manufacturers and are processed into cables using standard plastic extruders.

During the extrusion process, nylon is melted and shaped into thin coatings or sheathing layers over the main cable insulation. This combination of materials creates a durable, protective layer that enhances the overall performance of the cable.

Nylon cables are often used in conjunction with polyethylene (PE) or PVC insulation. By adding a nylon sheath over these more fragile materials, manufacturers create cables that can withstand tough environmental conditions while maintaining flexibility and strength.

Common Applications of Nylon Cable

Thanks to their strength and abrasion resistance, nylon cables have found a home in several industries and applications. Some of the most common uses of nylon cables include:

Electrical wiring: Nylon is frequently used as an abrasion-resistant coating over polyethylene or PVC-insulated electrical wires. This additional layer protects the insulation and ensures the wires remain intact even in challenging environments.

Aircraft wiring: Nylon is used in aircraft wiring to improve the cable's resistance to abrasion, as well as to aircraft fuels. Known as Nyvin cables, these wires are commonly used in aerospace due to their high strength and ability to withstand the demanding conditions of flight.

Petrochemical industry: Nylon cables are employed in the petrochemical industry, where they are used in conjunction with a layer of PE bonded to a heat-sealed aluminum/polymer tape. This combination creates an oil and chemical barrier, allowing nylon cables to replace traditional lead sheaths.

Ripcords: Nylon cords are also used as high-strength ripcords in cables. These cords run inside the cable sheath and allow technicians to easily strip back the sheath for installation or repair.

Reinforcing braids: Nylon is also used as a reinforcing braid in the sheaths of cables for applications that involve arduous conditions. This extra layer of strength ensures the cable can handle stress without breaking.

Standards Governing Nylon Cable

To ensure safety and performance, nylon cables are manufactured to meet several industry standards. These standards vary depending on the region and application but include specifications such as:

BSG 177: This British Standard outlines the requirements for cables used in telecommunications, where nylon is often used as a sheathing material.

BT Specifications: BT (British Telecom) sets specific standards for cables used in their telecommunications networks, many of which use nylon sheaths for added durability and protection.

How Nylon Compares to PUR (Polyurethane) Cables

When comparing nylon cables to other materials, one of the most common comparisons is with PUR (Polyurethane) cables. While both materials offer distinct advantages, there are several key differences between the two.

Nylon:

Excellent abrasion resistance

Lower resistance to high temperatures

Slight moisture absorption

Smooth surface that reduces friction

Resistant to oils and solvents, but only moderate resistance to acids

PUR:

Superior flexibility

High resistance to chemicals, oils, and greases

Can withstand extreme temperatures and conditions better than nylon

Better at resisting moisture absorption

Commonly used in flexible control cables, robotics, and drag chain applications

While PUR cables are better suited for applications that require extreme flexibility and chemical resistance, nylon cables excel in abrasion resistance and mechanical strength.

Nylon is also often more cost-effective than PUR, making it a popular choice for general-purpose applications.

Why Choose Nylon Cable?

Nylon cable is an excellent choice for applications that require strength, durability, and abrasion resistance. Whether you're working in the aerospace industry, telecommunications, or petrochemicals, nylon cables offer a reliable solution that can withstand demanding conditions.

While it may not have the same chemical resistance or flexibility as materials like PUR, its ability to handle mechanical stress and resist wear makes it a valuable option in many industrial environments.

Final Thoughts

Choosing the right cable for your application is essential for ensuring long-term performance and safety. Nylon cables offer an ideal combination of strength, abrasion resistance, and oil resistance, making them a versatile choice for a wide range of industries.

However, it's important to consider the specific requirements of your application when deciding between nylon, PUR, or other cable materials.

If you're looking for a high-strength, abrasion-resistant cable that can handle tough conditions, nylon cable could be the perfect solution for you. By understanding the unique properties of nylon and comparing it with other materials, you can make an informed decision that meets your needs.

For more information on nylon cables or to request a quote, contact us today. We offer a wide range of high-performance cables to suit your specific needs.