In today’s rapidly evolving world, safety and environmental concerns are at the forefront of many industries. One of the areas where these concerns are highly relevant is in the field of electrical cabling, particularly when it comes to fire safety and emissions.

This is where LSZH Thermoplastic Cable comes into play. But what exactly is this type of cable, and why is it becoming so important? Let’s dive into the details of LSZH Thermoplastic Cables and understand their significance in modern electrical installations.

The term LSZH stands for Low Smoke Zero Halogen. This means that when these cables are exposed to fire, they emit very little smoke and do not release harmful halogen gases. This is crucial in environments where fire safety is a priority.

In the event of a fire, traditional cables that contain halogens like chlorine, fluorine, and bromine can release toxic gases when burned.

These gases can cause serious health issues and also lead to significant damage to electronic equipment. LSZH Thermoplastic Cables eliminate this risk by being made from materials that are free from halogens.

Both LSZH Thermoplastic Cables and LSZH Cross-linked Cables share the same goal: minimizing smoke and harmful emissions during a fire. However, they differ in their material composition and manufacturing process.

There are several compelling reasons to choose LSZH Thermoplastic Cables over traditional PVC or other types of cables, especially in applications where safety is paramount. Let’s break down some of the key benefits:

In case of a fire, the materials used in LSZH Thermoplastic Cables produce far less smoke than traditional PVC cables. This is important for maintaining visibility and reducing the risk of inhalation of toxic fumes, which can be life-threatening.

For environments like office buildings, hospitals, and data centers, where large numbers of people or sensitive equipment are present, fire safety is critical.

Traditional PVC cables release harmful halogen gases, like chlorine, when exposed to fire. These gases can cause serious respiratory issues and create corrosive fumes that damage electronics.

LSZH Thermoplastic Cables are free of halogens, reducing the risk of both health hazards and damage to equipment.

In many regions, especially in Europe, the use of LSZH cables is mandated by building and safety codes. Standards like IEC 60092, IEC 60502, and BS 5266 specify the need for low smoke and zero halogen cables in various applications.

This ensures that cables meet strict safety requirements and provide a higher level of fire performance compared to older materials like PVC.

Since LSZH Thermoplastic Cables do not contain halogens, they are better for the environment. During manufacturing and disposal, halogen-containing materials can release harmful chemicals into the atmosphere.

By using LSZH materials, companies can reduce their environmental footprint and contribute to a cleaner, safer planet.

One of the key components in LSZH Thermoplastic Cables is polyolefin. This material is widely used in the cable industry due to its excellent electrical properties, flexibility, and fire-resistant characteristics.

The polyolefin-based thermoplastic compound is typically combined with other elements like EVA (ethylene-vinyl acetate) and various fillers, such as hydrated alumina, to enhance the fire retardant properties.

The compounding technology used to create LSZH Thermoplastic Cables is highly sophisticated. While the primary polymer, EVA, provides the base structure, fillers and other additives play an essential role in ensuring the cable performs optimally in demanding conditions.

For example, EVA can have varying levels of vinyl acetate content, which affects the material’s flexibility and resistance to fluids.

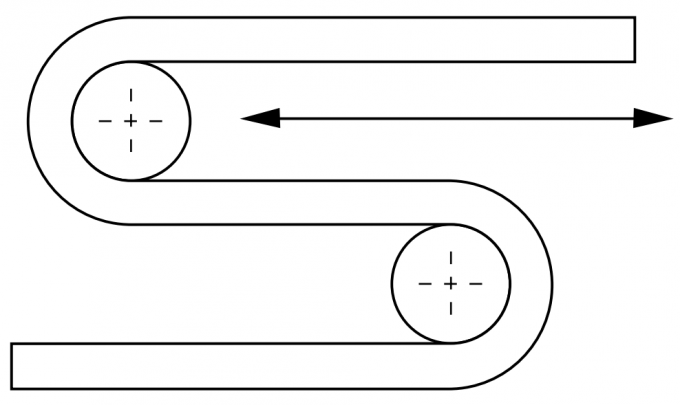

The manufacturing process of LSZH Thermoplastic Cables involves several critical steps to ensure the final product meets the required safety and performance standards.

Compounding: The first step is to blend the base material (typically polyolefins or EVA) with carefully selected fillers, color pigments, and processing aids. This mixture is essential for creating the low smoke, zero halogen properties of the cable.

Extrusion: Once compounded, the material is extruded using standard single screw extruders. The extrusion process shapes the material into the required form for insulation or sheathing.

Quality Control: To ensure the cables meet fire safety requirements, they undergo rigorous testing for factors like smoke emission, flame retardance, and halogen content.

LSZH Thermoplastic Cables are used in a wide range of applications, particularly where fire safety is critical. Let’s look at some common use cases:

In many industrial settings, armored cables are used to protect against mechanical damage. By using LSZH thermoplastic sheathing, these cables can maintain their fire performance while providing protection against physical impact.

In public buildings, fire alarm systems and emergency lighting are essential for keeping people safe during emergencies. LSZH Thermoplastic Cables are ideal for these systems because they minimize the risk of toxic smoke and corrosive gases.

Cables in subways, trains, and buses must meet strict fire safety regulations. LSZH Thermoplastic Cables ensure the safety of passengers by reducing smoke and hazardous emissions in case of a fire.

In data centers, protecting equipment from smoke and corrosive gases is crucial. LSZH Thermoplastic Cables help safeguard sensitive electronics and ensure business continuity in case of a fire.

When it comes to cable manufacturing, compliance with international standards is non-negotiable. LSZH Thermoplastic Cables meet a variety of recognized standards, such as:

By adhering to these standards, LSZH Thermoplastic Cables provide peace of mind for contractors, building owners, and safety inspectors.

The demand for LSZH Thermoplastic Cables continues to grow as industries prioritize fire safety and environmental sustainability.

With their superior fire performance, zero halogen content, and compliance with international standards, these cables are the future of electrical wiring in both commercial and industrial applications.

Whether you’re in construction, transportation, or telecommunications, investing in LSZH Thermoplastic Cables ensures safety, reliability, and compliance with modern regulations.

As industries evolve, the role of LSZH cables will only become more significant, paving the way for safer and more environmentally friendly electrical systems.

In an era where safety and environmental considerations are paramount, LSZH Thermoplastic Cables represent a smart, forward-thinking choice for any project.