The H07RN-F cable has a long and trusted history in the electrical world. It was designed to offer flexibility and strength in the most challenging environments. Initially developed for industrial applications, it is now a go-to solution for various industries, from construction to mining and everything in between.

This cable is not only known for its durability but also for its versatility and resistance to external elements like oils, chemicals, and abrasions.

Let’s dive deeper into why H07RN-F Rubber Insulated Cable is one of the most popular choices when it comes to power transmission in tough environments.

The H07RN-F Cable was developed as a solution to provide safe and reliable power transmission, especially in situations where cables might face significant wear and tear.

From the start, the goal was to create a cable that could handle harsh environmental conditions, including exposure to chemicals, oil, and physical abrasion. The result was a flexible, rubber-insulated cable designed to withstand a wide range of temperatures and mechanical stress.

This cable has grown in popularity due to its flexibility, which is especially important for applications where the cable needs to be frequently moved or flexed. Its neoprene rubber insulation is a key feature that provides exceptional resistance to chemicals and oils.

As a result, H07RN-F Rubber Insulated Cable is now widely used in various sectors and is trusted by industries across the globe.

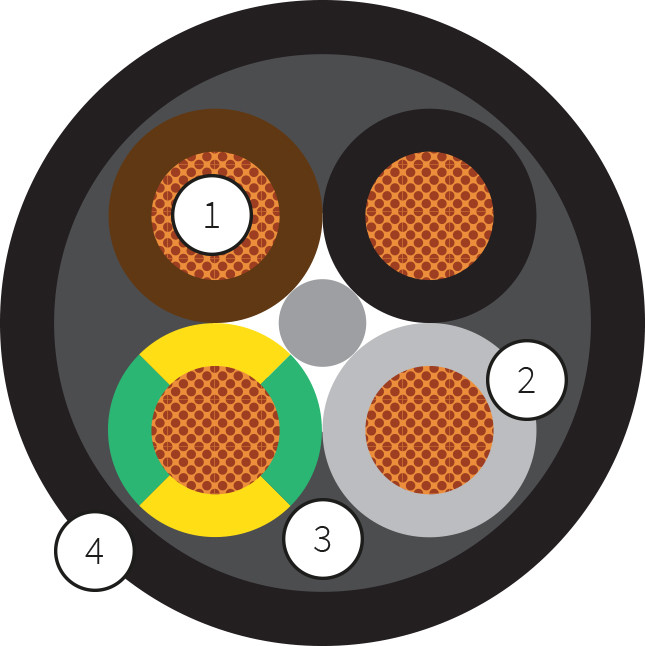

H07RNF Power Cables are built to withstand tough conditions while delivering safe and reliable electrical connections. Here are some of the standout features:

Durability and Flexibility

One of the most important qualities of the H07RN-F neoprene Cables is their flexibility. This makes them ideal for applications that involve frequent cable movement or the need to fit into tight spaces. The rubber insulation allows them to bend and flex without damaging the core wires.

Temperature Resistance

These cables are rated for temperatures ranging from -30°C to 90°C, making them suitable for a wide range of environments. Whether you’re working in freezing temperatures or high-heat situations, the H07RNF Electric Cables will hold up.

Chemical and Oil Resistance

Thanks to the neoprene rubber insulation, H07RN-F Flexible Rubber Cables are resistant to oils, chemicals, and other harsh substances. This makes them ideal for industries like mining, construction, and manufacturing, where exposure to such materials is common.

Impact Resistance

Unlike some other cable types, the H07rn-f trailing Cables are designed to withstand physical impacts. The tough neoprene jacket gives these cables a level of durability that makes them suitable for environments where they might be subjected to heavy wear and tear.

Voltage Rating

The H07RNF 3g4 Cables are typically rated for 450/750V, making them perfect for medium voltage applications. This rating ensures they are safe and efficient in delivering power without causing electrical hazards.

Multiple Cores for Flexibility

The H07RNF Power Cables are available in both single-core and multi-core types. The single-core cables are better for applications that require higher current ratings, while the multi-core versions (which can have 2, 3, or even 19 cores) are ideal for more complex power needs.

For instance, the H07rnf 5g 6.0mm Sq Neoprene Rubber Cables are perfect for systems that require multiple phases of power transmission.

Given their robust design, H07RNF 3g4 Cables are used in various industries.

Here’s where you’re likely to find these cables in action:

Construction Sites

On construction sites, power tools, generators, and temporary lighting systems often require durable cables that can handle rough handling and exposure to the elements.

The Pure Copper H07rnf Wire Tough Rubber Cables offer excellent power transmission in such environments, ensuring equipment operates smoothly even in demanding conditions.

Industrial Settings

Factories, plants, and other industrial environments often deal with chemicals, oils, and physical stress. The H07RN-F neoprene Cables provide the toughness needed to keep operations running safely.

Their ability to resist impact, abrasion, and temperature variations makes them perfect for machinery and power distribution in industrial applications.

Outdoor Applications

Due to their weather resistance, H07RNF Electric Cables are also widely used outdoors. Whether in construction or outdoor events, these cables can handle exposure to rain, sun, and dirt.

The neopreen kabel h07rnf can withstand challenging outdoor conditions without compromising performance.

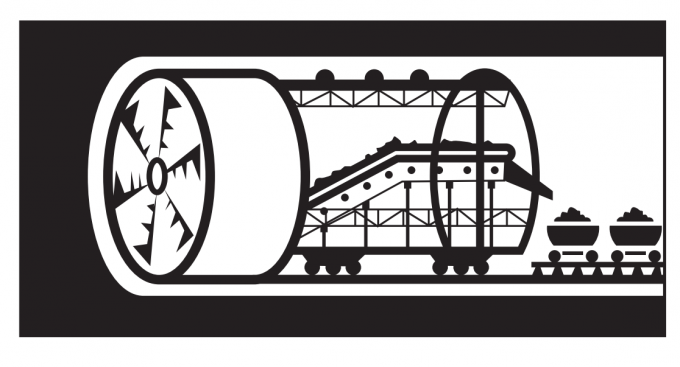

Mining and Tunneling

In industries where cables are frequently exposed to harsh environmental conditions, such as mining, the 750V H07rnf 70mm2 Flexible Rubber Welding Cables offer an excellent solution.

Their resistance to abrasion and chemicals makes them particularly suitable for these environments.

Marine and Offshore Applications

Given their resistance to moisture and chemicals, Cables H07rnf 1X120 SQMM are used in marine and offshore settings. These cables can withstand exposure to saltwater and other corrosive elements, ensuring a long service life.

Welding Equipment

The 2.5mm2 H07rnf Cables and H07rn-F Rubber Cables 1.5mm2 are ideal for welding equipment. They offer flexibility and durability, ensuring they can handle the high temperatures and physical demands of welding tasks.

How does the H07RNF Cable stack up against other popular cable types, such as PUR cables?

Let’s break it down:

Temperature Range

While H07RN-F neoprene Cables can handle temperatures up to 90°C, PUR cables often have a broader temperature range, making them better for environments that experience extreme heat or cold. However, for most medium-temperature environments, the H07RN-F Flexible Rubber Cables provide more than enough resistance.

Chemical Resistance

Both cable types offer excellent resistance to chemicals, but H07RNF Power Cables are more versatile in industrial environments where exposure to oils and chemicals is frequent. Their neoprene rubber insulation gives them an edge in handling a wide range of substances.

Flexibility

When it comes to flexibility, both cable types perform well. However, H07RNF cables are generally preferred for applications requiring frequent bending and movement due to their rubber insulation, which provides a softer and more flexible covering.

The H07RNF Cable is an excellent choice for industries that demand durability, flexibility, and resistance to external elements like oils, chemicals, and physical impacts. With their ability to handle a range of temperatures and harsh environments, these cables are trusted across multiple industries.

Whether you need a cable for construction, industrial applications, or even mining, the H07RNF Electric Cables will deliver reliable performance.

Additionally, their availability in single-core and multi-core types, like H07rnf 5g 6.0mm Sq Neoprene Rubber Cables, makes them versatile enough to suit various power needs.

Whether you’re running a small machine or powering a large piece of industrial equipment, these cables have the strength and flexibility to meet your requirements.

When it comes to tough environments, choosing the right cable is essential for safety and efficiency. The H07RN-F Rubber Insulated Cable is your go-to solution for delivering power in the most demanding conditions.