Are you looking for cables designed for high-flex, continuous motion applications, especially in environments where space is limited and durability is essential? Your search ends here.

Festoon Cable could be the perfect solution for your needs. Whether you're working with cranes, hoists, or other moving equipment, Festoon Cable offers the flexibility, strength, and reliability to keep your operations running smoothly.

In this article, we’ll dive deep into the history of Festoon Cable, its unique features, and the specific uses that make it a standout choice for a variety of industrial applications.

Whether you're familiar with festoon systems or just beginning to explore your options, this comprehensive guide will help you understand why Festoon Cable might be exactly what your business needs.

The History of Festoon Cable: From Simple Beginnings to Industrial Powerhouse

The History of Festoon Cable: From Simple Beginnings to Industrial Powerhouse

Festoon cables originated from the need to provide a durable, flexible, and high-performance cable solution for moving machinery in industrial environments. Initially, traditional cables were used, but they couldn't handle the continuous bending and flexing that occurs when machinery moves back and forth.

As industries like manufacturing, shipping, and construction advanced, so did the demand for a more resilient and flexible cable solution.

Enter Festoon Cable, a flat, highly flexible cable designed specifically to withstand the rigors of motion and environmental stress.

Over the years, Festoon Cable has evolved with improvements in materials and design. Today, it incorporates modern innovations such as high-strand-count conductors, flame-retardant jackets, and resistance to oils, chemicals, and extreme temperatures.

These enhancements have made Festoon Cable the go-to choice for industries requiring reliable and long-lasting performance under continuous motion.

When selecting a cable for your crane, hoist, or other moving equipment, you want something that will perform consistently, even in the harshest conditions.

Festoon Cable is designed for just that. Let’s explore some of the key features that make this cable a leader in its field:

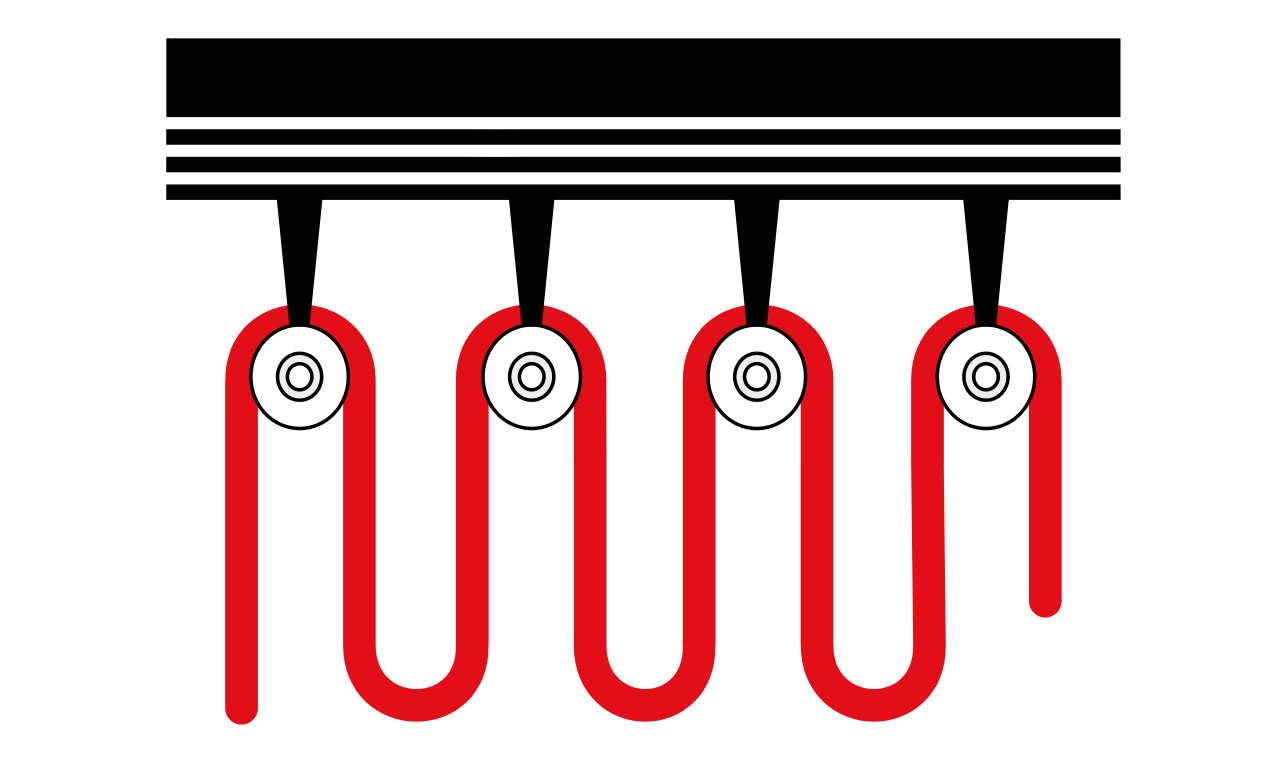

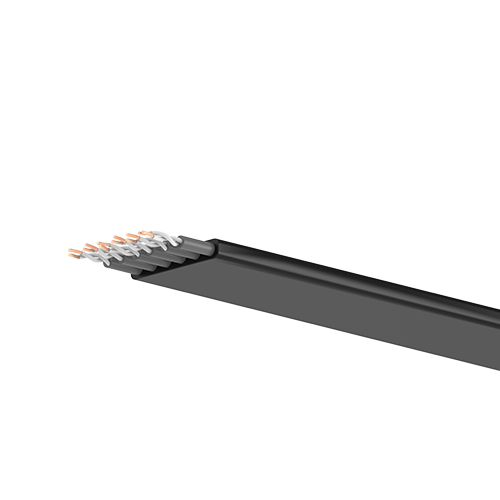

One of the most defining characteristics of Festoon Cable is its flat construction. This flat design allows the cable to handle continuous flexing and bending without breaking down. Additionally, flat cables take up less space than traditional round cables, which makes them ideal for installations where space is tight or where cables need to run in confined spaces.

The flat design also helps to avoid coiling and twisting, which can happen with round cables. This is especially important in environments where the cable is moved or wound repeatedly, such as in cranes or hoists.

Festoon Cables typically feature a high strand count, meaning they consist of many small, flexible wires bundled together. This design increases the cable’s ability to handle repeated bending and flexing, making it ideal for applications where the cable will be in constant motion.

The higher the strand count, the more flexible and durable the cable.

Festoon Cables are built to last in harsh industrial environments. Made with materials like neoprene or PVC, these cables are resistant to flames, oil, fat, acid, and other chemicals. Both neoprene and PVC are suitable for use in damp or dry environments, but neoprene offers superior resistance to extreme weather conditions, making it the better choice for outdoor applications.

Additionally, festoon cables are resistant to ozone and UV exposure, which helps extend their lifespan when used outdoors. For industries like shipping and construction, where cables are exposed to sun, rain, and other elements, this feature is invaluable.

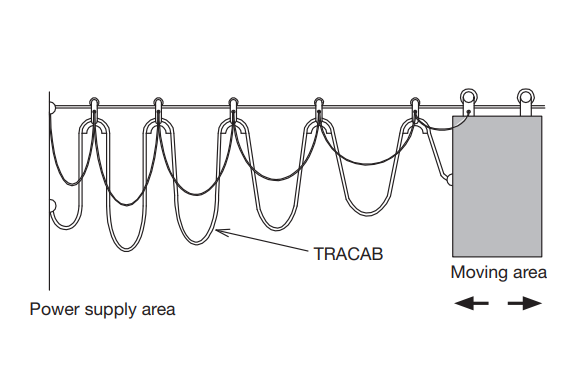

The small bending radius of Festoon Cable allows it to bend and flex in tight spaces without damaging the internal wiring. This makes the cable perfect for applications where space is limited or where the cable needs to be routed around tight corners.

The flexibility provided by the small bending radius also helps in applications like cranes and hoists, where the cable is constantly moving.

Many Festoon Cables come with flame-retardant properties, making them suitable for environments where fire safety is a concern. Additionally, the cable’s UV resistance ensures it remains durable even when exposed to sunlight for extended periods.

Festoon cables can be manufactured to meet RoHS compliance and CE certification standards, ensuring that the materials used are safe for the environment and meet stringent quality standards.

This is especially important for industries that need to adhere to specific regulations.

Thanks to their unique combination of features, Festoon Cables are used in a wide range of industries and applications. Let’s explore some of the most common uses:

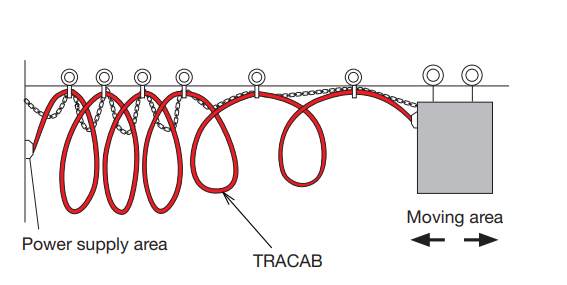

One of the most prominent applications of Festoon Cable is in crane and hoist systems. These systems require cables that can withstand constant movement without fraying or losing connectivity.

Festoon Cables are perfect for this purpose due to their flexibility and durability. They can handle continuous motion while providing reliable power and control signals to the equipment.

Within the crane industry, Festoon Cable is used in two main configurations:

C-Track Festoon Systems: These systems use the cable to provide power to the runway, control to the bridge crane, and low-voltage control to a separate pendant station.

Tagline Festoon Systems: These are used to provide power and control to the hoist system or smaller cranes.

In seaports, where equipment is constantly loading and unloading cargo, festoon cables are essential. They provide reliable power to cranes, hoists, and other machinery used in port operations.

The resistance to moisture and chemical exposure makes them well-suited to the harsh conditions often found at seaports.

Festoon Cables are also widely used in industrial manufacturing applications, where they provide power to moving equipment like assembly lines, robots, and conveyors. Their ability to withstand constant flexing and bending makes them ideal for these dynamic environments.

Another area where Festoon Cable shines is in lumber mills, where heavy-duty equipment like conveyors and hoists are constantly in motion. Additionally, these cables are used in jetways at airports to provide reliable power to boarding bridges and other airport systems.

In automotive manufacturing, where robotic arms and other machinery are in constant motion, Festoon Cables provide the necessary power and control.

Their ability to handle continuous motion without degradation ensures that operations can continue smoothly without unexpected downtime due to cable failure.

One of the best things about Festoon Cable is the customization options available. Depending on your specific needs, you can select different materials for the cable jacket, insulation, and internal wiring.

For example, some industries require cables that are resistant to UV radiation or high temperatures, while others need cables that can handle harsh chemicals or oil exposure.

Cables can also be customized in terms of color, with yellow being the most common jacket color. However, other colors are available to match specific branding or safety requirements.

Additionally, festoon cables can be designed to meet specific flame resistance ratings or safety certifications, such as RoHS or CE standards.