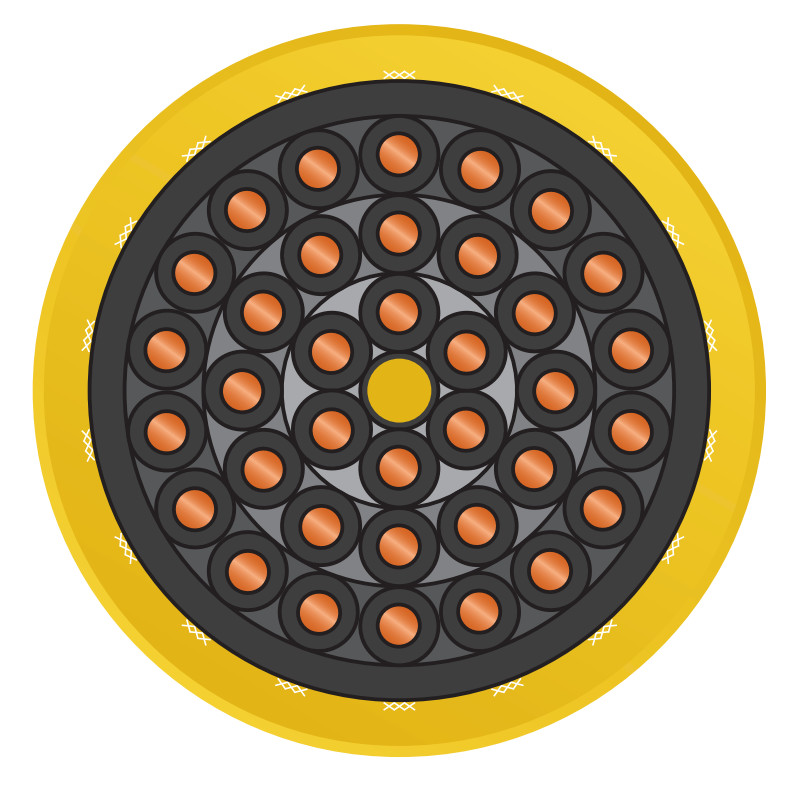

When choosing a cable for various electrical applications, one name that stands out is Ethylene Propylene Rubber (EPR) cable.

This cable offers excellent flexibility, insulation, and durability. Whether used in low-voltage or high-voltage systems, EPR cables are designed to handle challenging environments while ensuring electrical safety.

This article dives deep into the world of EPR/EPDM cables, explaining their composition, uses, and why they are the right choice for your projects.

EPR (Ethylene Propylene Rubber) and EPDM (Ethylene Propylene Diene Monomer) are often mentioned together, but they have some key differences.

Despite their differences, both EPR and EPDM are known for their high-temperature resistance, waterproof qualities, and excellent weathering resistance. These features make them ideal for industrial and heavy-duty applications.

When looking for cables that can handle tough environments and maintain performance over time, EPR/EPDM cables stand out. Here’s why:

EPR cables are designed to offer outstanding dielectric strength, which refers to their ability to resist electrical breakdown.

This makes them perfect for medium-voltage and high-voltage applications where electrical insulation is critical. For example, in medium voltage cables, EPR provides superior insulation compared to other materials like PVC or XLPE.

One of the standout qualities of EPR and EPDM cables is their flexibility, even in low temperatures. They remain flexible down to -25°C and can be specially compounded to work as low as -50°C.

This makes them ideal for outdoor and cold-weather installations where other cables may become brittle.

Both EPR and EPDM cables can withstand high operating temperatures. They are rated for continuous operation at temperatures of up to 90°C.

This makes them suitable for environments with fluctuating temperatures or extreme heat exposure, like factories, offshore installations, or mines.

These cables are resistant to a wide range of environmental factors. EPR/EPDM cables are known for their excellent resistance to ozone, UV radiation, and weathering.

Whether used in indoor or outdoor environments, these cables can handle exposure to harsh elements without deteriorating.

Due to their molecular structure, EPR and EPDM cables offer exceptional water resistance, making them perfect for marine applications, underground installations, and other areas prone to moisture.

Another important feature of EPR and EPDM cables is that they are halogen-free, which means they do not release harmful gases when exposed to fire.

This makes them safer for use in confined spaces such as tunnels, ships, and public buildings where fire safety is a concern.

Now, you might be wondering how EPR cables compare to Chlorinated Polyethylene (CPE) cables. Both are commonly used in industrial settings, but they have some important differences.

When it comes to electrical insulation, EPR wins hands down. Its dielectric strength is much higher than CPE, making it ideal for high-voltage applications. CPE, however, is typically used in low-voltage settings and may not perform as well when exposed to higher voltages.

Both materials are flexible, but EPR/EPDM cables tend to offer more consistent flexibility, especially in colder temperatures. CPE cables can stiffen in cold environments, which may limit their usability in certain applications.

If you’re working in an environment with exposure to oils, solvents, or chemicals, CPE cables are a better option. While EPR and EPDM are durable, they have poor resistance to oils and solvents.

CPE excels in these environments but lacks some of the electrical performance of EPR.

Both EPR and CPE have flame-retardant qualities, but CPE cables typically perform better in this area. However, EPR and EPDM cables still meet many industry standards for fire resistance and are halogen-free, which adds an extra layer of safety in fire-prone environments.

Thanks to their versatility and durability, EPR/EPDM cables are used in a wide range of industries. Some common applications include:

The exceptional water resistance of EPR cables makes them perfect for use in marine environments. Whether installed on ships, offshore platforms, or submarines, these cables can withstand constant exposure to moisture without degrading.

In the mining industry, cables must withstand abrasion, extreme temperatures, and exposure to chemicals. EPR cables, with their superior durability and flexibility, are commonly used in mining equipment, ensuring reliable power delivery even in the toughest conditions.

Because EPR and EPDM cables are flexible and can withstand harsh weather, they are ideal for railway systems and public transportation. The cables are often used in rolling stock, providing reliable insulation and heat resistance in various climates.

In industries such as manufacturing, oil and gas, and construction, cables are exposed to challenging environments. EPR/EPDM cables provide the durability and flexibility needed to power equipment and machinery safely and efficiently.

For low- and medium-voltage power distribution, EPR cables are a popular choice due to their excellent electrical properties and insulation. Whether used in underground power systems or above-ground installations, EPR cables deliver reliable performance.

When choosing EPR/EPDM cables, it's important to ensure they meet the required industry standards. Some of the relevant standards include:

These standards ensure that EPR/EPDM cables meet strict safety and performance requirements, offering peace of mind when used in critical applications.

Ethylene Propylene Rubber (EPR) and Ethylene Propylene Diene Monomer (EPDM) cables are exceptional choices for anyone looking for reliable, flexible, and durable cables that can handle tough environments.

Whether you're working on a marine project, in mining, or simply need a cable that offers excellent insulation and thermal properties, EPR/EPDM cables are the way to go.

With their high dielectric strength, heat resistance, and waterproofing qualities, these cables outperform many other materials in critical applications.

While CPE cables have their advantages in terms of chemical resistance and flame retardancy, EPR cables are the better choice for high-voltage applications where electrical performance is key.

If you’re considering EPR/EPDM cables for your next project, you’re making a solid choice. Their combination of flexibility, durability, and insulation capabilities makes them ideal for a wide range of industries.

Explore the world of EPR/EPDM cables today and discover why they are trusted by professionals across the globe for their superior performance and reliability.

For more details on how EPR/EPDM cables can fit into your project, feel free to contact us or request a quote today!