In this article, we'll explore the history, features, and applications of EPR trailing cables. By the end, you'll have a clear understanding of why they are essential in various demanding environments.

The development of trailing cables goes hand in hand with the advancement of heavy machinery and industrial equipment. In the early days, rubber trailing cables were made from natural rubber to provide insulation and protection for the wires within.

However, as industries grew more demanding, the limitations of natural rubber became evident. The need for better weather resistance, flexibility, and durability in harsh environments led to the introduction of synthetic rubbers, including EPR (ethylene propylene rubber).

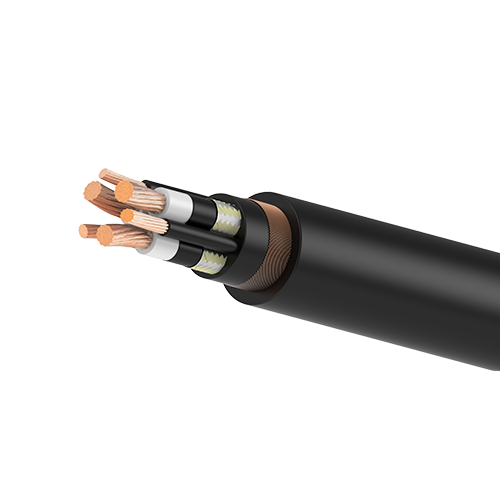

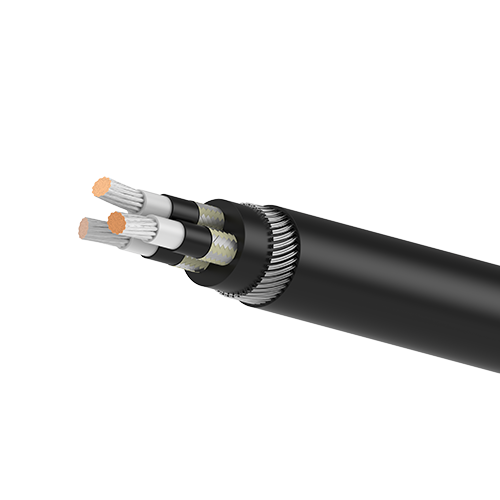

EPR quickly became a preferred material for trailing electrical cables because of its superior properties, such as resistance to heat, ozone, and mechanical stress. Today, EPR trailing cables are widely used in various industrial applications where reliability, flexibility, and durability are paramount.

EPR trailing cables offer several key characteristics that make them ideal for use in harsh environments:

High Flexibility: EPR trailing cables are known for their flexibility, even in low temperatures. This makes them perfect for use in environments where the cable needs to be bent or coiled frequently, such as cranes and mining equipment. Flexible trailing cables are also easier to install and handle, reducing downtime in operations.

Temperature Resistance: One of the standout features of EPR trailing cables is their wide temperature range. They can operate efficiently in temperatures as low as -55°C and as high as +250°C.

This makes them suitable for use in both extremely cold and hot environments. Whether it's the freezing temperatures of a mining site or the high heat of a steel mill, these cables can handle the challenge.

Ozone and Weather Resistance: EPR is highly resistant to ozone, UV radiation, and weather conditions, which allows EPR trailing cables to be used in outdoor environments without degradation.

This is especially important for applications like trailing cables for cranes or outdoor construction equipment that are exposed to the elements.

Chemical Resistance: EPR trailing rubber cables also offer excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents.

This makes them suitable for use in environments where they may come into contact with hazardous substances, such as mining trailing cables or power station equipment.

Electrical Insulation: With high dielectric strength, EPR cables provide excellent insulation, ensuring safety and efficiency in electrical applications.

This is crucial in environments where electrical reliability is a top priority, such as in nuclear & thermal power stations.

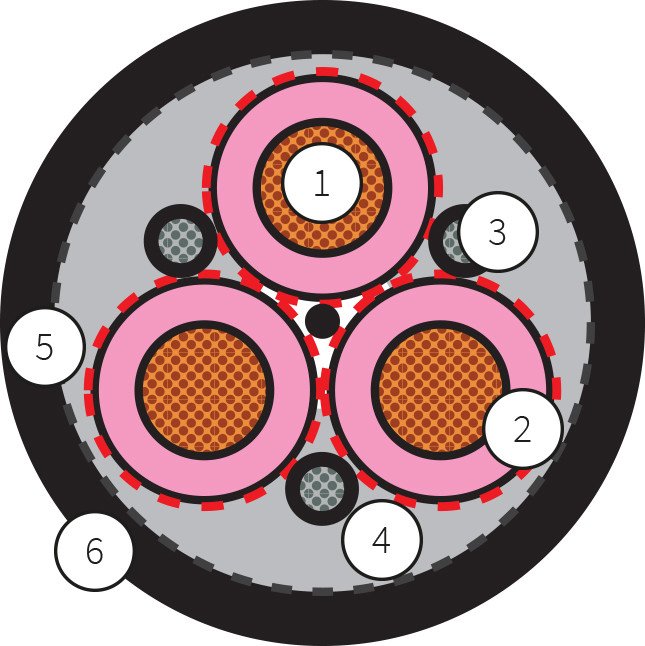

There are various types of EPR trailing cables depending on the specific application and industry needs. Here are some commonly used types:

241.1 Trailing Cable: This type of trailing cable is often used in mining and heavy industrial applications where flexibility and durability are essential.

The 241.1 trailing cable offers excellent resistance to mechanical stress and harsh environments.

Nitrile Trailing Cable: Nitrile trailing cables are designed for environments where oil and chemical resistance is important.

They are often used in industries like oil refineries and power plants.

4 Core Trailing Cable: These cables feature four conductors, making them ideal for applications where multiple circuits are needed. The 4 core trailing cable is commonly used in cranes, construction equipment, and other heavy-duty machinery.

High Mast Trailing Cable: This type of cable is used in high-mast lighting systems and other tall structures that require reliable power transmission. High mast trailing cables are designed to handle vertical movements and mechanical stresses.

While EPR trailing cables are known for their durability and flexibility, there are other types of trailing cables used in specific applications.

For example, Neoprene Trailing CPE Sheath Flexible Rubber Cable is often used in environments where chemical resistance is critical, while 6/10kV Flexible Trailing Cables with three-core conductors (like 3 Core * 50mm cables) are used in high-voltage applications.

One of the key differences between EPR trailing rubber cables and other types is their high temperature resistance. EPR cables can withstand higher temperatures compared to many other trailing cables, making them a better choice for extreme environments.

EPR trailing cables are used in a wide range of industries due to their versatility and durability. Some of the common applications include:

Mining: In the mining industry, equipment and cables are subjected to extreme mechanical stress, harsh weather, and rough handling.

EPR trailing cables for mining are designed to withstand these conditions, providing reliable power and control for machinery.

Cranes and Hoists: Trailing cables for cranes need to be flexible and durable to handle the constant movement and mechanical stress.

EPR trailing flat rubber cables are ideal for these applications due to their flexibility and weather resistance.

Power Stations: Nitrile trailing cables are often used in nuclear & thermal power stations where resistance to chemicals and heat is essential.

These cables ensure safe and reliable power transmission in high-risk environments.

Construction Equipment: Heavy construction equipment, such as excavators and cranes, require trailing cables that can withstand constant bending and torsion.

Elastomeric trailing cables made from EPR are perfect for these applications.

Ships and Ports: Trailing cables for ships and high mast trailing cables are used in maritime environments where saltwater, weather, and mechanical stress are major concerns.

In conclusion, EPR trailing cables are an excellent choice for a variety of heavy-duty industrial applications.

Their flexibility, durability, temperature resistance, and chemical resistance make them ideal for use in harsh environments such as mining, power stations, construction, and maritime industries.

When choosing the right cable for your application, it’s essential to consider the specific demands of your environment. Whether you need a nitrile trailing cable for chemical resistance or a 4 core trailing cable for complex electrical systems, EPR trailing rubber cables offer a reliable and long-lasting solution.

So, if you’re looking for trailing cables that can handle the toughest conditions, EPR trailing cables are the way to go. Whether you need them for mining, cranes, or power stations, these cables are designed to perform under the most demanding circumstances.

By choosing EPR trailing cables, you ensure that your equipment is powered reliably, even in the most challenging environments.

Explore our wide range of trailing wires and cables, including trailing cords, and find the perfect solution for your industrial needs today!