Type 409 or Type 275 Cable, Which One Should I Choose?

When it comes to selecting the right cable for your project, the decision can be overwhelming. Type 409 and Type 275 cables are two of the most commonly used options in various industries, and while they might seem similar at first glance, each has its own strengths and is suited to different applications.

Making the right choice depends on understanding the specific needs of your project and the characteristics of each cable type.

In this article, we’ll take a closer look at Type 409 and Type 275 cables, comparing their features, benefits, and the scenarios where each excels. By the end, you should have a clearer idea of which cable is the best fit for your needs.

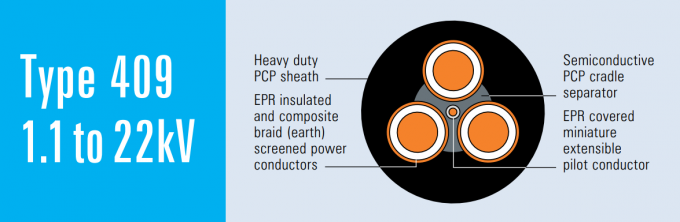

Understanding Type 409 Cable

Type 409 cable is known for its durability and flexibility. It’s commonly used in mining operations, construction sites, and other demanding environments where cables need to withstand harsh conditions. One of the standout features of Type 409 is its high resistance to wear and tear, making it ideal for situations where the cable will be subjected to heavy mechanical stress.

Key Features of Type 409 Cable:

High Durability: Designed to last in tough environments, Type 409 cable is built to resist physical damage from abrasion, impact, and rough handling.

Flexibility: Despite its ruggedness, Type 409 cable remains flexible, allowing it to be used in applications where bending and movement are frequent.

Temperature Resistance: This cable can operate effectively in a wide range of temperatures, making it suitable for both indoor and outdoor use.

Moisture and Chemical Resistance: Type 409 is also resistant to moisture and chemicals, which is crucial in environments where exposure to water, oils, or other substances is likely.

Given these features, Type 409 cable is often the go-to choice for heavy-duty applications, particularly in industries like mining, construction, and heavy manufacturing.

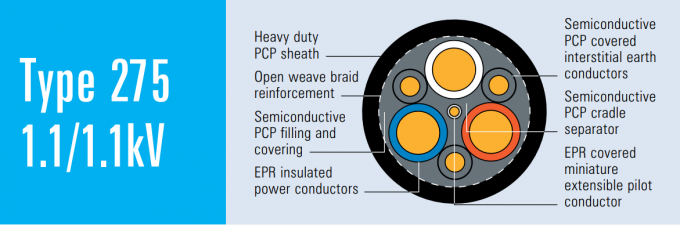

Understanding Type 275 Cable

On the other hand, Type 275 cable is designed with a different set of priorities in mind. While it may not be as rugged as Type 409, it excels in environments where electrical performance and cost-efficiency are key considerations.

Type 275 is typically used in less demanding environments, where the cable is not subjected to extreme mechanical stress but where reliable electrical performance is essential.

Key Features of Type 275 Cable:

Cost-Effective: Type 275 is generally more affordable than Type 409, making it an attractive option for projects where budget constraints are a primary concern.

Good Electrical Performance: This cable offers reliable electrical conductivity, making it suitable for a wide range of standard electrical applications.

Adequate Durability: While not as tough as Type 409, Type 275 still provides sufficient durability for many applications, particularly in less physically demanding environments.

Ease of Installation: Thanks to its lighter weight and flexibility, Type 275 cable is easier to install, which can save time and labor costs on the job site.

Type 275 cable is often chosen for residential, commercial, and light industrial applications where the environment is more controlled and the cable is not exposed to severe conditions.

Comparing the Two: Which One Should You Choose?

When deciding between Type 409 and Type 275 cable, the key is to consider the specific requirements of your project.

Here are some factors to keep in mind:

1. Environment:

- If your project involves a harsh environment with extreme temperatures, heavy mechanical stress, or exposure to chemicals and moisture, Type 409 is likely the better choice. Its durability and resistance to environmental factors make it ideal for tough conditions.

- For projects in more controlled environments where the cable won’t be exposed to as much wear and tear, Type 275 can be a more cost-effective option without sacrificing performance.

2. Budget:

- If budget constraints are a significant concern, Type 275 offers a more affordable solution while still providing reliable performance for many applications.

- However, it’s important to weigh the potential long-term costs of maintenance and replacement. In harsh environments, the extra investment in Type 409 could save money in the long run by reducing the frequency of cable replacements.

3. Application Requirements:

- Consider the specific needs of your application. For example, if the cable will be subject to frequent bending and movement, Type 409’s flexibility might be necessary.

- If the primary concern is ensuring consistent electrical performance in a standard environment, Type 275 may be sufficient.

Real-World Examples

Let’s look at a few scenarios to illustrate when each type of cable might be the best choice:

Scenario 1: Mining Operations In a mining operation where cables are dragged across rough surfaces and exposed to abrasive materials, Type 409 cable is the obvious choice. Its rugged construction ensures it can withstand the physical demands of the environment, reducing the likelihood of damage and minimizing downtime.

Scenario 2: Commercial Building Wiring For wiring in a commercial building where the cables will be installed in walls or ceilings and won’t be exposed to harsh conditions, Type 275 cable provides a reliable and cost-effective solution. The controlled environment means that the cable won’t need the extreme durability of Type 409, and the lower cost of Type 275 can help keep the project within budget.

Scenario 3: Outdoor Industrial Equipment If you’re running cables to outdoor industrial equipment that will be exposed to the elements, Type 409 is likely the better choice due to its superior moisture and temperature resistance. This ensures that the cable can continue to perform reliably even in challenging outdoor conditions.

Choosing between Type 409 and Type 275 cable comes down to understanding the demands of your specific application.

Type 409 offers exceptional durability and resistance to harsh conditions, making it ideal for heavy-duty industrial use. Type 275, on the other hand, provides reliable electrical performance at a lower cost, making it a smart choice for less demanding environments.

Ultimately, the right choice will depend on balancing your needs for durability, flexibility, electrical performance, and cost. By carefully considering these factors, you can ensure that you select the cable that will deliver the best performance and value for your project.

If you’re still unsure which cable is right for you, or if you have specific requirements that need to be addressed, don’t hesitate to contact the experts at Feichun Special Cable Co., Ltd.. We’re here to help you navigate your options and provide the best solution for your unique needs.