When installing reeling cables for cranes, material handling systems, and other heavy-duty machinery, precision and attention to detail are essential.

Reeling cables, like the (N)SHTÖU, (N)GRDGCGÖU, (N)TSFLCGEWÖU, and (N)TSKCGEWÖU, are designed to handle extreme mechanical stress while maintaining flexibility and durability. However, ensuring these cables function properly and last for years requires following specific installation steps.

This guide will walk you through the essential steps for installing flexible electric reeling cables, offer tips on maintaining the correct tension and alignment, and provide solutions to common issues.

Whether you're working with cranes, stackers, or ship loaders, adhering to these instructions will help prevent unnecessary wear and downtime.

Installing reeling cables the right way is crucial for maintaining system efficiency and avoiding costly repairs.

Cables can be vulnerable to wear, kinks, and damage if not installed correctly. Here are some reasons why proper installation is critical:

Prevents torsion damage: Incorrect handling can twist the cable, resulting in dangerous internal damage.

Reduces wear and tear: Proper alignment and tension reduce the stress on the cable during operation.

Improves longevity: Cables that are installed correctly last longer and require fewer repairs.

Ensures safety: Improper cable installation can lead to power failures or dangerous electrical hazards.

Before starting the installation process, you need to ensure that the environment and equipment are ready for the cable. This preparation can prevent common issues that arise due to environmental factors or mechanical stress.

Selecting the correct reeling cable is essential. Different environments and systems may require specific cable types. For instance:

(N)SHTÖU is ideal for flexible applications under heavy mechanical stress.

(N)GRDGCGÖU works well for harsh outdoor environments where high mechanical demands are present.

(N)TSFLCGEWÖU is designed for high torsional stress applications.

(N)TSKCGEWÖU is suitable for high reeling speeds and compact designs.

Reeling cables are delicate yet robust. Careful handling during installation will preserve their structure and functionality:

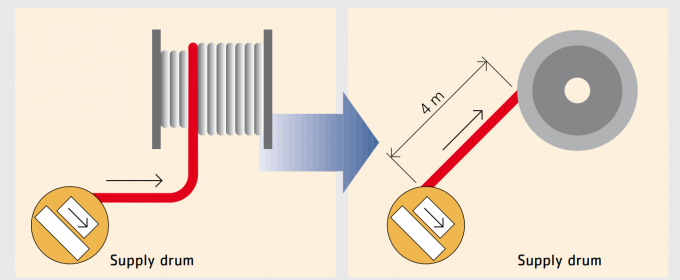

Do not stretch the cable before laying it on the operating drum.

Dekinking or stretching the cable before installation could lead to torsion and damage.

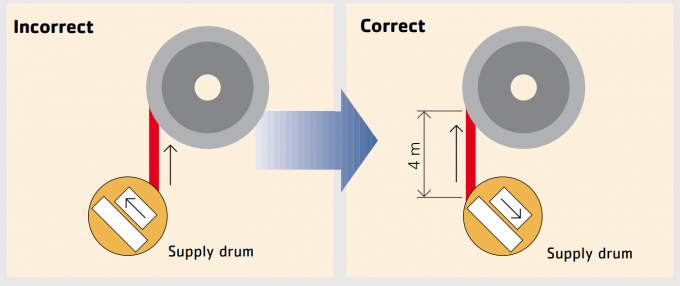

The cable should be unwound directly from the supply drum and laid out carefully.

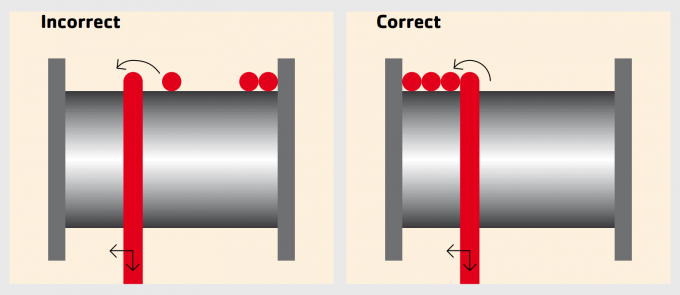

Never pull the cable over the flange. This causes the cable to twist by 360° with every loop, resulting in permanent damage.

The direction of the cable winding is critical to avoid torsion. The manufacturing process dictates the cable's winding direction.

For power cables, the lay is always left-hand (S-type), while for control cables, it is right-hand.

When starting the winding process:

For power cables, begin from the left side of the reel.

For control cables, begin from the right side of the reel.

This ensures that the winding pattern stays clean and correct throughout the cable's use, even when the reel lacks guidance.

Start by carefully unwinding the cable from the supply drum. Avoid pulling the cable across rough surfaces or sharp edges, as this can damage the outer insulation.

Ensure that the starting point for winding the cable matches the winding direction of the cable lay:

Left-hand (S-type) for power cables.

Right-hand for control cables.

Positioning the cable in the correct direction avoids unnecessary twists and torsion, which can weaken the internal wiring over time.

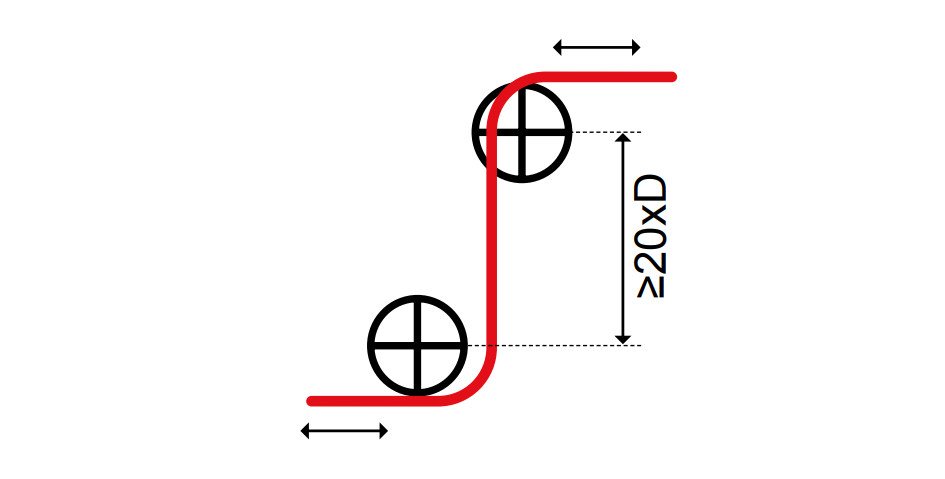

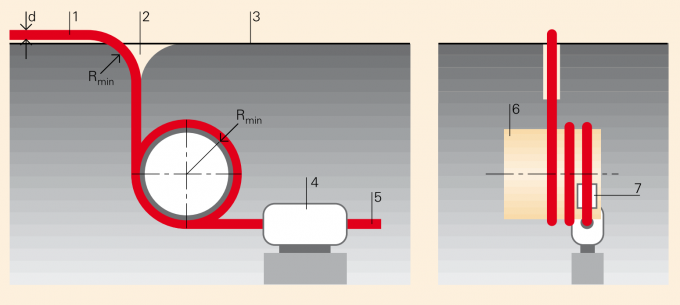

The bending radius of the cable is an important factor that should be adhered to during installation. The minimum permissible bending radius is determined by the cable diameter.

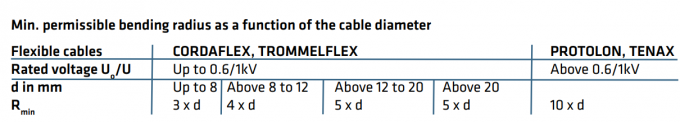

Here are the minimum bending radii for different cable diameters:

For cables up to 8mm, the minimum radius is 3 times the cable diameter.

For cables above 8mm to 12mm, the minimum radius is 4 times the diameter.

For cables above 12mm to 20mm, the minimum radius is 5 times the diameter.

Using the correct bending radius reduces the risk of damaging the cable's internal structure, preventing insulation breakdown or conductor fatigue.

Strain relief is essential to minimize wear and tear on the cable. For installations involving underfloor infeeds, the infeed point should allow for minimal deflection from the cable path.

The use of compensation cylinders and large-area design cable clips can effectively reduce cable wear.

Ensure that strain relief mechanisms are attached only after the second winding on the reel. This helps avoid adding unnecessary strain during the cable's first few revolutions on the drum.

When working with reeling cables in electric systems, understanding voltage ratings is essential to avoid overloads or failures. These cables are designed to operate under specific voltage conditions:

Cables with rated voltage up to 0.6/1kV: Suitable for use in AC and DC installations with voltage deviations of no more than 20% for AC systems and 50% for DC systems.

Cables with rated voltage above 0.6/1kV: These cables can handle three-phase and single-phase AC systems with voltage deviations up to 20%.

Always ensure that the cable's rated voltage aligns with your system’s operating voltage. Overloading the cable can lead to insulation failure or even catastrophic system failures.

Even experienced professionals can make mistakes during reeling cable installation. Here are some common pitfalls and how to avoid them:

Overstretching the cable: Stretching or pulling the cable too tight during installation can weaken the structure and reduce the lifespan of the cable.

Incorrect bending radius: Failing to follow the recommended bending radius can lead to breaks in the cable’s internal wiring.

Reeling in the wrong direction: Always make sure to wind the cable from the correct side (left or right) based on the cable type (power or control). Incorrect winding causes unnecessary stress and can lead to failure.

Skipping strain relief: Not using proper strain relief can result in excessive tension at critical points, leading to faster wear and potential system downtime.

Once the reeling cable is installed, it’s important to test the system for electrical continuity and mechanical stress. Here are a few steps to ensure your system runs smoothly:

Electrical testing: Test for insulation resistance and continuity. Make sure the cable meets the voltage requirements of your system.

Mechanical testing: Run the reeling system to check for any signs of improper winding or excess tension on the cable.

Routine inspections: Periodically check the cable for signs of wear, especially at strain points and connection areas. Regular maintenance can extend the life of the cable and prevent unexpected failures.

Proper installation of reeling cables like (N)SHTÖU, (N)GRDGCGÖU, (N)TSFLCGEWÖU, and (N)TSKCGEWÖU is essential for achieving optimal performance and ensuring long-lasting durability.

By following the guidelines outlined in this Reeling Cable Installation Guide, you can avoid common pitfalls and ensure that your cables operate smoothly for years to come.

Whether you are working with cranes, bunkering equipment, or other material handling systems, taking the time to install and maintain your reeling cables correctly will result in fewer repairs, less downtime, and a safer working environment.

Always consult the manufacturer’s specifications, adhere to voltage ratings, and use proper strain relief to keep your cables in the best possible condition.