In the mining industry, choosing the right power cable is crucial for maintaining the safety, efficiency, and reliability of operations. Two key factors in selecting the correct mining power cable are determining the voltage level and the cross-sectional area of the cable.

These factors directly influence the cable's ability to handle electrical load, resist environmental stress, and ensure the safe transmission of power.

In this article, we’ll guide you through the process of determining the appropriate voltage level and cross-sectional area for your mining power cables.

We’ll cover the basics, including why these factors matter, the formulas you’ll need, and how to apply them in real-world situations. Whether you’re a seasoned engineer or someone new to the field, this guide is designed to be both informative and easy to understand.

Before diving into the calculations, it’s important to understand why these two factors are so critical in mining operations.

The voltage level of a mining power cable determines the maximum voltage it can safely carry without breaking down or becoming unsafe. This is particularly important in mining environments, where equipment often requires high voltage to operate efficiently.

Using a cable with the incorrect voltage level can lead to insulation failure, electrical shorts, or even catastrophic accidents like fires or explosions.

The cross-sectional area of a cable refers to the thickness of the conductors within it, measured in square millimeters (mm²). This factor is crucial because it determines how much current the cable can carry without overheating.

A cable with a cross-sectional area that is too small for the current load can become dangerously hot, leading to insulation damage and, potentially, equipment failure.

The voltage level for mining power cables is typically determined by the operational requirements of the mining equipment and the power distribution system. Here’s how you can determine the appropriate voltage level:

Start by identifying the voltage requirements of the equipment that the cable will be powering. This information is usually provided by the equipment manufacturer and is critical in selecting a cable that can handle the required voltage.

The length of the cable can impact the voltage drop over its length. In mining operations, where cables often run long distances, this can be a significant factor.

The voltage drop must be minimized to ensure efficient operation of the equipment.

The voltage drop (V_drop) can be calculated using the formula:

Where:

= Current (in Amperes)

= Resistance of the cable per unit length (in Ohms per meter)

= Length of the cable (in meters)

To ensure the voltage drop is within acceptable limits, the cable’s voltage rating should be high enough to account for this drop, particularly in long cable runs.

In South Africa, as in many other countries, the voltage levels for mining cables are often dictated by industry standards.

These standards ensure that cables are safe and suitable for use in specific mining environments. Common standards include the SANS 1507 series, which outlines the requirements for various types of cables, including those used in mining.

Determining the correct cross-sectional area of a cable is essential to ensure it can handle the current load without overheating. Here’s how to calculate it:

The first step is to determine the current load that the cable needs to carry. This is calculated based on the power requirements of the equipment and the operating voltage using the formula:

Where:

= Current (in Amperes)

= Power (in Watts)

= Voltage (in Volts)

= Power factor (typically between 0.8 and 1 for most mining equipment)

For example, if you have a piece of equipment that requires 10,000 Watts of power and operates at 400 Volts with a power factor of 0.9, the current load would be:

Once you have the current load, you can determine the appropriate cross-sectional area of the cable using standard tables or formulas that relate the current-carrying capacity of the cable to its cross-sectional area. A simplified formula is:

Where:

= Cross-sectional area (in mm²)

= Current (in Amperes)

= Current density (in Amperes per square millimeter, typically between 4-6 A/mm² for copper cables)

Using our previous example with a current of 27.78 Amperes and assuming a current density of 5 A/mm²:

In this case, a cable with a cross-sectional area of 6 mm² would be appropriate.

The calculated cross-sectional area may need to be adjusted based on environmental factors such as ambient temperature, installation conditions, and whether the cable is buried or exposed.

Higher ambient temperatures or installation in confined spaces can reduce the cable's current-carrying capacity, requiring a larger cross-sectional area.

Let’s put this all together with a practical example. Suppose you’re tasked with selecting a power cable for a conveyor system in a surface mine.

The system requires 20,000 Watts of power and operates at 600 Volts with a power factor of 0.85. The cable will run a distance of 100 meters in an environment with an ambient temperature of 40°C.

Calculate the Current Load:

Determine the Cross-Sectional Area: Assuming a current density of 5 A/mm²:

Given the environmental conditions, you might round up to a 10 mm² cable to ensure safety and durability.

Check the Voltage Drop: Assume a resistance of 0.1 Ohms per meter for the cable:

This voltage drop is too high, so you may need to select a cable with a larger cross-sectional area or use a different cable configuration to minimize the drop.

Choosing the right mining power cable is more than just a matter of picking a cable off the shelf. It requires careful consideration of both the voltage level and the cross-sectional area to ensure that the cable can safely and efficiently handle the demands of your mining operation.

By understanding the formulas and factors involved, you can make informed decisions that enhance the safety, efficiency, and longevity of your mining equipment.

Whether you’re dealing with high-powered equipment in a deep underground mine or managing surface operations in harsh environments, high-quality mining cables tailored to your specific needs are essential.

Don’t leave your cable selection to chance—use the guidelines and calculations provided in this article to ensure that your cables are up to the task.

For more information on selecting the right mining cables or to discuss your specific needs, contact Feichun Cables today. We’re here to help you power your operations safely and efficiently.

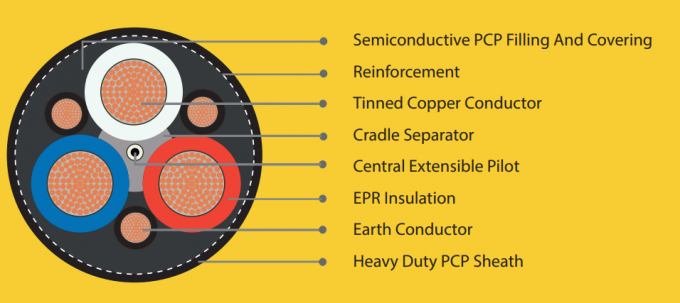

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.