In today’s industrial world, the demand for durable, high-performance cables is at an all-time high. From processing plants to offshore rigs, industries need cables that can withstand the toughest conditions. One such cable that stands out is the Chloro Sulphonated Polyethylene (CSP) Cable, often referred to as CSPE Cable.

If you’re looking for a cable that can handle extreme environments, protect against fluids and chemicals, and ensure longevity in outdoor conditions, then CSP Cable could be your perfect solution. Let’s dive into what makes CSP Cable such a powerful player in the cable industry and why it might be the right fit for your needs.

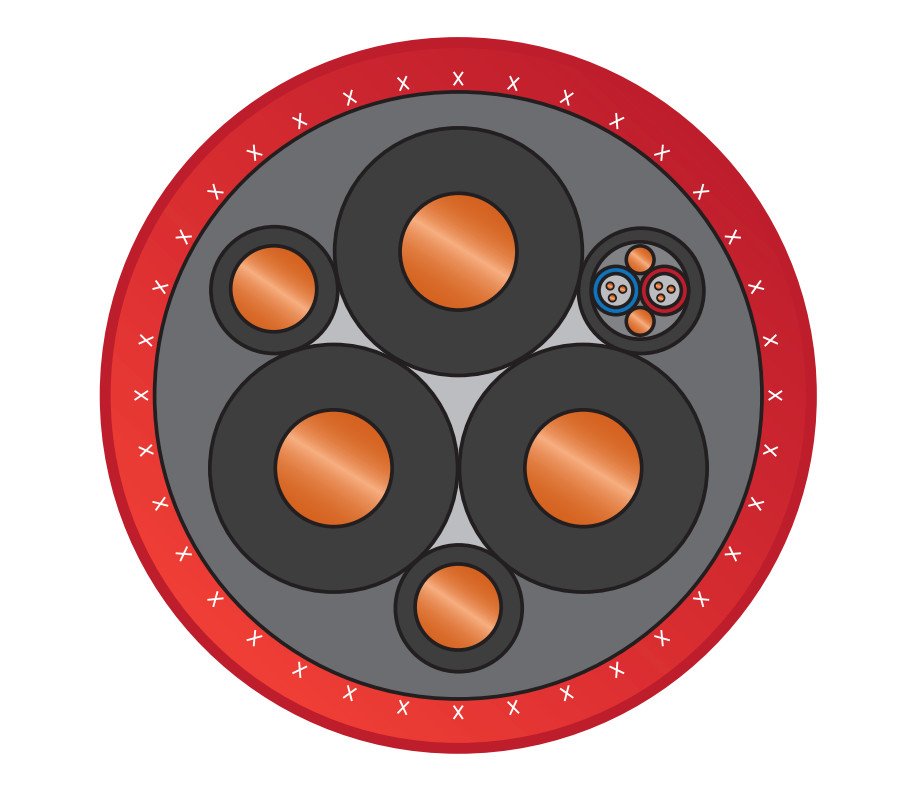

CSP Cable is made from Chloro Sulphonated Polyethylene, a thermoset, cross-linked polymer. This means that it’s formed by chemically bonding its molecules to create a durable, rubber-like material. Once cross-linked, CSP Cable becomes highly resistant to various environmental and mechanical factors, making it ideal for harsh and demanding conditions.

The CSP polymer was designed to be flexible yet strong, providing excellent physical properties and electrical insulation. Its unique blend of monomers creates a real rubber compound, giving it outstanding resistance to fluids, solvents, and mechanical wear.

The benefits of CSP Cable go beyond its ability to handle tough environments. Here are some of the top reasons why industries rely on it:

Mechanical Strength: CSP Cable excels in environments where cables are exposed to impact, abrasion, crushing, and chipping. Whether it’s in a construction zone or deep in a mine, this cable can handle significant wear and tear without losing its integrity.

Resistance to Environmental Hazards: Unlike many other materials, CSP has a high resistance to ageing caused by sunlight and oxidation. Its low water absorption and immunity to ozone make it perfect for outdoor use, where weather conditions can often degrade ordinary cables.

Temperature Performance: CSP Cables can perform across a wide range of temperatures, from as low as -40°C up to +120°C. It’s a great option for industries that require cables to function in both freezing and extremely hot conditions.

Chemical Resistance: One of the standout features of CSP Cable is its resistance to hydrocarbons, oils, greases, and fuels. This makes it the go-to choice in oil & gas, mining, and chemical processing plants, where exposure to these substances is common.

Fire Resistance: While CSP contains chlorine, which prevents it from being classified as halogen-free, it still provides excellent fire resistance. This means it can be used in environments where fire hazards exist, although it’s less favored in areas where low smoke emissions are critical.

Both CSP and CPE Cables are highly regarded for their durability and flexibility in harsh conditions. But they differ in key areas that could impact your choice, depending on the application.

Chemical Composition and Performance:

CPE Cable (Chlorinated Polyethylene) offers solid resistance to chemicals and mechanical damage, but CSP Cable takes this up a notch. Due to its enhanced molecular structure, CSP Cable performs better in environments exposed to more aggressive chemicals, fuels, and solvents.

Mechanical Strength:

CPE provides good strength and flexibility, but CSP is known for its superior mechanical properties. It can withstand more impact and abrasion, making it a better option for extreme conditions, like offshore rigs and mining operations.

Fire and Smoke Properties:

While both CPE and CSP are fire-resistant, CSP offers stronger flame-retardant capabilities. However, it contains chlorine, which makes it unsuitable for applications requiring halogen-free properties. CPE, on the other hand, may be more appropriate if low smoke and halogen-free features are needed.

Cost:

CSP is typically more expensive than CPE, but the performance justifies the cost. If your project involves harsh chemicals, extreme temperatures, and heavy-duty environments, investing in CSP Cable could save you in the long run by reducing the need for replacements and repairs.

CSP Cable is incredibly versatile, finding use across a wide range of industries where strength, durability, and resistance to environmental hazards are essential. Here are some of its most common applications:

Oil & Gas Industry: In environments where exposure to hydrocarbons, oils, and fuels is common, CSP Cable shines. It’s used in offshore rigs, refineries, and other locations where durability and chemical resistance are paramount.

Mining: Mines, particularly those deep underground, need cables that can handle mechanical stress, abrasive conditions, and exposure to chemicals. CSP Cable is favored in mining operations due to its abrasion resistance and impact strength.

Processing Plants: Industries like chemical manufacturing and refining benefit from CSP Cables because of their ability to resist damage from airborne chemicals and harsh processing environments.

Outdoor Installations: Given its low water absorption and resistance to sunlight and ozone, CSP Cable is ideal for long-term outdoor installations, including power lines, control cables, and heavy machinery wiring.

Construction and Heavy-Duty Equipment: Whether it’s temporary power in construction sites or heavy machinery requiring long-lasting cable solutions, CSP Cables can handle the physical demands of the job.

The production of CSP Cable requires a careful balance of compounding and vulcanization to achieve the required properties. Here's how it's made:

Compounding: CSP is formulated using standard rubber compounding equipment. The mixture is created to produce the final properties that make the cable resistant to fluids, chemicals, and wear.

Vulcanization: This process is crucial for turning CSP into a cross-linked material. Typically, sulfur-based systems are used for vulcanization, but peroxides can also be employed for specific requirements. The result is a robust, high-performance cable ready to tackle tough conditions.

Extrusion: The compounded CSP material is extruded using a single screw process, and then vulcanized using either CV tubes or autoclave methods.

For any cable to be effective, it must meet industry standards. CSP Cables are manufactured in compliance with several important international standards:

While CSP Cable provides many performance benefits, its environmental impact should be considered. Because it contains chlorine, CSP cannot be classified as a halogen-free material.

In the event of a fire, CSP can release toxic fumes, making it less suitable for applications where low smoke and halogen-free properties are essential.

However, for industries prioritizing durability, chemical resistance, and mechanical strength, the environmental trade-offs may be outweighed by the cable's performance and lifespan.

Whether you're dealing with heavy-duty machinery, harsh outdoor conditions, or chemical-heavy environments, CSP Cable offers the toughness and reliability needed to keep operations running smoothly.

While it's not the cheapest option on the market, its superior mechanical strength, chemical resistance, and durability make it an investment worth considering.

With CSP Cable, you're not just getting a cable—you’re getting a long-term solution designed to stand up to the toughest challenges.