Surface mining operations rely heavily on trailing cables to deliver power to mobile equipment like drills, shovels, and conveyors. While these cables are essential for keeping operations running smoothly, they also pose significant safety risks if not handled properly.

High potential incidents involving trailing cables can lead to serious injuries, equipment damage, and costly downtime. Understanding these risks is crucial for anyone involved in surface mining, from operators to maintenance teams.

In this article, we’ll take a closer look at the most common high-potential incidents involving trailing cables at surface mines. We’ll also explore the safety hazards and electrical risks associated with these incidents, and provide tips on how to avoid them in your daily work.

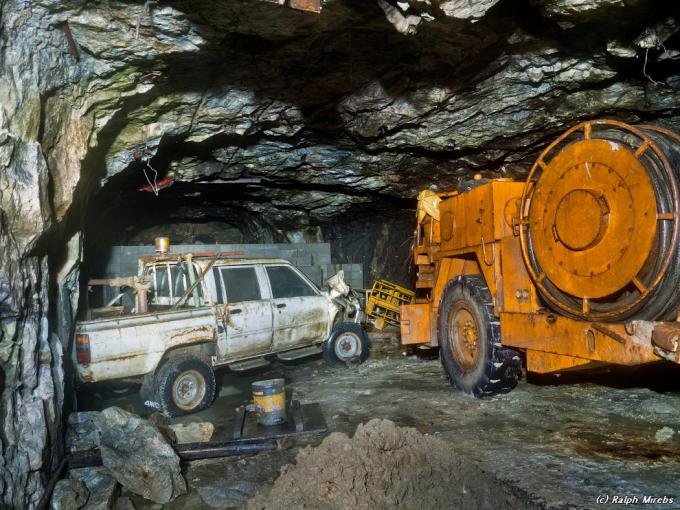

Before diving into the potential incidents, it’s important to understand the role of trailing cables in surface mining. These cables are specifically designed to provide power to large, mobile mining equipment that is constantly moving around the mine site.

Unlike stationary cables, trailing cables need to be flexible and durable enough to withstand continuous movement, heavy loads, and harsh environmental conditions.

However, the same factors that make trailing cables so essential also make them prone to damage and failure. As they are dragged across rough terrain, exposed to extreme temperatures, and subjected to constant bending and twisting, trailing cables are at a higher risk of being compromised.

When not properly managed, these risks can escalate into high-potential incidents that endanger both workers and equipment.

Let’s explore some of the most common high-potential incidents that can occur with trailing cables at surface mines. These incidents are not only dangerous but can also lead to significant operational disruptions.

One of the most frequent incidents involving trailing cables is cable damage due to crushing or pinching. This often occurs when heavy machinery, such as haul trucks or shovels, runs over the cable, pinching it between the equipment and the ground.

This kind of damage can compromise the cable’s insulation, leading to exposed conductors and increasing the risk of electrical shock or fire.

To mitigate this risk, it’s crucial to keep a close eye on the positioning of trailing cables during operations. Properly routing cables away from high-traffic areas and using cable protection systems can help prevent crushing and pinching incidents.

Electrical overloads and short circuits are another major risk associated with trailing cables.

These incidents typically occur when the cable is asked to carry more current than it is rated for, leading to overheating and potentially causing the insulation to melt. This can result in a short circuit, which not only damages the cable but can also cause equipment failure and pose a significant fire hazard.

To avoid electrical overloads, it’s important to ensure that the trailing cables being used are appropriately rated for the equipment they are powering. Regular inspections and monitoring of the cable’s condition can also help detect any signs of overheating before they escalate into a full-blown incident.

As trailing cables are dragged across rocky surfaces, they are subjected to constant abrasion. Over time, this can wear down the cable’s outer jacket, exposing the inner insulation and conductors.

If left unchecked, this wear and tear can lead to electrical faults, including arcing, short circuits, and even explosions in extreme cases.

Implementing proper cable handling techniques and using cables with reinforced jackets designed for high-abrasion environments can help reduce the risk of wear and tear.

Additionally, regularly inspecting cables for signs of abrasion and replacing them as needed is essential for maintaining a safe working environment.

While trailing cables are designed to be flexible, excessive bending and flexing can eventually lead to cable failure. This is particularly true if the cable is bent beyond its recommended radius or if it is subjected to repeated flexing in the same spot.

Over time, this can cause the internal conductors to break or the insulation to crack, leading to electrical faults and potential safety hazards.

To prevent cable failure from bending and flexing, it’s important to follow the manufacturer’s guidelines on minimum bend radius and avoid placing undue stress on the cable.

Ensuring that cables are properly supported and not subjected to constant, repetitive movements can also help extend their lifespan.

Water ingress is another significant risk for trailing cables, particularly in surface mining environments where cables may be exposed to rain, snow, or standing water. When water penetrates the cable’s insulation, it can lead to short circuits and corrosion of the conductors. In severe cases, water ingress can cause the cable to fail entirely, resulting in power outages and equipment downtime.

To protect against water ingress, it’s important to use trailing cables with waterproof or water-resistant insulation. Additionally, ensuring that cable terminations and connectors are properly sealed can help prevent water from entering the cable.

The incidents described above highlight the potential safety hazards and electrical risks associated with trailing cables at surface mines. These risks include:

While the risks associated with trailing cables are significant, they can be managed with proper precautions and best practices. Here are some key steps to help avoid high-potential incidents:

Regular inspections are essential for identifying potential issues before they lead to an incident. Check for signs of damage, wear, and tear, as well as any signs of overheating or water ingress. Address any issues promptly to prevent them from escalating.

Proper handling of trailing cables can help prevent damage and extend their lifespan. This includes routing cables away from high-traffic areas, avoiding excessive bending, and using cable protection systems to prevent crushing and abrasion.

Ensure that the trailing cables being used are appropriately rated for the equipment and environmental conditions at your mine site. Using the right cables can help prevent electrical overloads and reduce the risk of failure.

Proper training is key to preventing incidents involving trailing cables. Ensure that all workers are trained in the correct handling, inspection, and maintenance of cables, as well as the potential risks involved.

Regularly monitor the electrical loads on your trailing cables to ensure they are not being overloaded. If necessary, upgrade to higher-rated cables to handle the power demands of your equipment.

Trailing cables are an essential part of surface mining operations, but they also pose significant risks if not properly managed.

By understanding the common high-potential incidents involving these cables and taking steps to prevent them, you can help ensure a safer and more efficient working environment.

At Feichun Cables, we offer a range of trailing cables specifically designed to withstand the harsh conditions of surface mining. Our cables are built with durability and safety in mind, helping you minimize risks and keep your operations running smoothly.

Contact us today to learn more about our products and how they can help you avoid high-potential incidents at your mine.